Comparts has over 15 years of experience working with a wide range of technologies and methods to achieve high-level products and solutions.

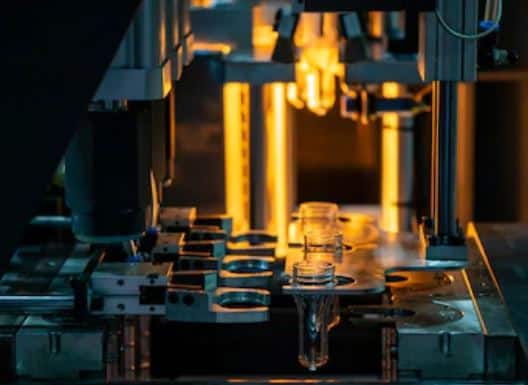

Fabrics and fibres are pre-impregnated by the materials manufacturer, under heat and pressure or with solvent, with a pre-catalysed resin, followed by drying using a vacuum oven or an autoclave.

Pre-impregnated materials (prepregs) are utilized in high-performance applications when weight and mechanical properties are top priority due to their reinforced structure resulting from combining the properties of the original materials.

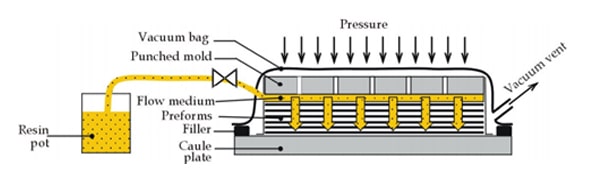

A highly permeable draining fabric is placed on top of the pre-form fibers and infused with resin.

Differential pressure is created by a vacuum at the vent of the system; this results in the impregnation of the compressible pre-form in the transverse direction.

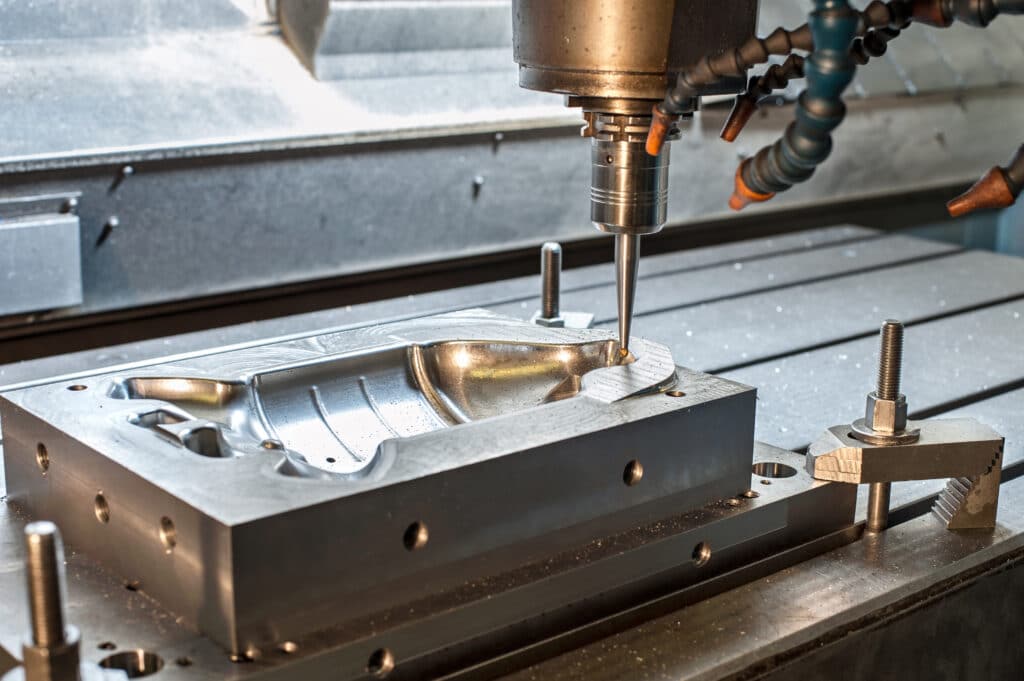

CNC cutting and milling for precise measurements of various materials-wood, plastic, composite materials and more.

The composites industry has a continual need for innovative tooling solutions to enable new applications and product improvements and address the constant demand for reductions in lead time and costs. Comparts uses advanced technologies to provide rapid production of highly capable composite tooling across a broad range of sizes, complexity, and cure temperatures.

Need more details? Contact us

We are here to assist. Contact us by phone, email or via our Social Media channels.

@ All rights reserved Comparts LTD 2022

3 Nahshon St. Petah Tikva , Israel | +972 03 904423 | info@comparts.co.il